Plasticity of von Mises#

This tutorial aims to demonstrate an efficient implementation of the plasticity

model of von Mises using an external operator defining the elastoplastic

constitutive relations written with the help of the 3rd-party package Numba.

Here we consider a cylinder expansion problem in the two-dimensional case in a

symmetric formulation.

This tutorial is based on the original implementation of the problem via legacy FEniCS 2019 and its extension for the modern FEniCSx in the setting of convex optimization. A detailed conclusion of the von Mises plastic model in the case of the cylinder expansion problem can be found in [Bonnet et al., 2014]. Do not hesitate to visit the mentioned sources for more information.

We assume the knowledge of the return-mapping procedure, commonly used in the solid mechanics community to solve elastoplasticity problems.

Notation#

Denoting the displacement vector \(\boldsymbol{u}\) we define the strain tensor \(\boldsymbol{\varepsilon}\) as follows

Throughout the tutorial, we stick to the Mandel-Voigt notation, according to which the stress tensor \(\boldsymbol{\sigma}\) and the strain tensor \(\boldsymbol{\varepsilon}\) are written as 4-size vectors with the following components

Denoting the deviatoric operator \(\mathrm{dev}\), we introduce two additional quantities of interest: the cumulative plastic strain \(p\) and the equivalent stress \(\sigma_\text{eq}\) defined by the following formulas:

where \(\boldsymbol{e} = \mathrm{dev}\boldsymbol{\varepsilon}\) and \(\boldsymbol{s} = \mathrm{dev}\boldsymbol{\sigma}\) are deviatoric parts of the stain and stress tensors respectively.

Problem formulation#

The domain of the problem \(\Omega\) represents the first quarter of the hollow cylinder with inner \(R_i\) and outer \(R_o\) radii, where symmetry conditions are set on the left and bottom sides and pressure is set on the inner wall \(\partial\Omega_\text{inner}\). The behaviour of cylinder material is defined by the von Mises yield criterion \(f\) with the linear isotropic hardening law (3)

where \(\sigma_0\) is a uniaxial strength and \(H\) is an isotropic hardening modulus, which is defined through the Young modulus \(E\) and the tangent elastic modulus \(E_t = \frac{EH}{E+H}\).

Let V be the functional space of admissible displacement fields. Then, the weak formulation of this problem can be written as follows:

Find \(\boldsymbol{u} \in V\) such that

The external force \(F_{\text{ext}}(\boldsymbol{v})\) represents the pressure inside the cylinder and is written as the following Neumann condition

where the vector \(\boldsymbol{n}\) is the outward normal to the cylinder surface and the loading parameter \(q\) is progressively adjusted from 0 to \(q_\text{lim} = \frac{2}{\sqrt{3}}\sigma_0\log\left(\frac{R_o}{R_i}\right)\), the analytical collapse load for the perfect plasticity model without hardening.

The modelling is performed under assumptions of the plane strain and an associative plasticity law.

In this tutorial, we treat the stress tensor \(\boldsymbol{\sigma}\) as an

external operator acting on the strain tensor

\(\boldsymbol{\varepsilon}(\boldsymbol{u})\) and represent it through a

FEMExternalOperator object. By the implementation of this external operator,

we mean an implementation of the return-mapping procedure, the most common

approach to solve plasticity problems. With the help of this procedure, we

compute both values of the stress tensor \(\boldsymbol{\sigma}\) and its

derivative, so-called the tangent moduli \(\boldsymbol{C}_\text{tang}\).

As before, in order to solve the nonlinear equation (4) we need to compute the Gateaux derivative of \(F\) in the direction \(\boldsymbol{\hat{u}} \in V\):

The advantage of the von Mises model is that the return-mapping procedure may be performed analytically, so the stress tensor and the tangent moduli may be expressed explicitly using any package. In our case, we the Numba library to define the behaviour of the external operator and its derivative.

Implementation#

Preamble#

from collections.abc import Callable, Sequence

from functools import partial

from mpi4py import MPI

from petsc4py import PETSc

import matplotlib.pyplot as plt

import numba

import numpy as np

from demo_plasticity_von_mises_pure_ufl import plasticity_von_mises_pure_ufl

from utilities import build_cylinder_quarter, find_cell_by_point

import basix

import ufl

from dolfinx import fem

from dolfinx.fem.bcs import DirichletBC

from dolfinx.fem.forms import Form

from dolfinx.fem.function import Function

from dolfinx.fem.petsc import NonlinearProblem, apply_lifting, assemble_vector, set_bc

from dolfinx_external_operator import (

FEMExternalOperator,

evaluate_external_operators,

evaluate_operands,

replace_external_operators,

)

Here we define geometrical and material parameters of the problem as well as some useful constants.

R_e, R_i = 1.3, 1.0 # external/internal radius

E, nu = 70e3, 0.3 # elastic parameters

E_tangent = E / 100.0 # tangent modulus

H = E * E_tangent / (E - E_tangent) # hardening modulus

sigma_0 = 250.0 # yield strength

lmbda = E * nu / (1.0 + nu) / (1.0 - 2.0 * nu)

mu = E / 2.0 / (1.0 + nu)

# stiffness matrix

C_elas = np.array(

[

[lmbda + 2.0 * mu, lmbda, lmbda, 0.0],

[lmbda, lmbda + 2.0 * mu, lmbda, 0.0],

[lmbda, lmbda, lmbda + 2.0 * mu, 0.0],

[0.0, 0.0, 0.0, 2.0 * mu],

],

dtype=PETSc.ScalarType,

)

deviatoric = np.eye(4, dtype=PETSc.ScalarType)

deviatoric[:3, :3] -= np.full((3, 3), 1.0 / 3.0, dtype=PETSc.ScalarType)

mesh, facet_tags, facet_tags_labels = build_cylinder_quarter()

k_u = 2

V = fem.functionspace(mesh, ("Lagrange", k_u, (mesh.geometry.dim,)))

# Boundary conditions

bottom_facets = facet_tags.find(facet_tags_labels["Lx"])

left_facets = facet_tags.find(facet_tags_labels["Ly"])

bottom_dofs_y = fem.locate_dofs_topological(V.sub(1), mesh.topology.dim - 1, bottom_facets)

left_dofs_x = fem.locate_dofs_topological(V.sub(0), mesh.topology.dim - 1, left_facets)

sym_bottom = fem.dirichletbc(np.array(0.0, dtype=PETSc.ScalarType), bottom_dofs_y, V.sub(1))

sym_left = fem.dirichletbc(np.array(0.0, dtype=PETSc.ScalarType), left_dofs_x, V.sub(0))

bcs = [sym_bottom, sym_left]

def epsilon(v):

grad_v = ufl.grad(v)

return ufl.as_vector([grad_v[0, 0], grad_v[1, 1], 0, np.sqrt(2.0) * 0.5 * (grad_v[0, 1] + grad_v[1, 0])])

k_stress = 2 * (k_u - 1)

ds = ufl.Measure(

"ds",

domain=mesh,

subdomain_data=facet_tags,

metadata={"quadrature_degree": k_stress, "quadrature_scheme": "default"},

)

dx = ufl.Measure(

"dx",

domain=mesh,

metadata={"quadrature_degree": k_stress, "quadrature_scheme": "default"},

)

Du = fem.Function(V, name="displacement_increment")

S_element = basix.ufl.quadrature_element(mesh.topology.cell_name(), degree=k_stress, value_shape=(4,))

S = fem.functionspace(mesh, S_element)

sigma = FEMExternalOperator(epsilon(Du), function_space=S)

n = ufl.FacetNormal(mesh)

loading = fem.Constant(mesh, PETSc.ScalarType(0.0))

v = ufl.TestFunction(V)

F = ufl.inner(sigma, epsilon(v)) * dx - ufl.inner(loading * -n, v) * ds(facet_tags_labels["inner"])

# Internal state

P_element = basix.ufl.quadrature_element(mesh.topology.cell_name(), degree=k_stress)

P = fem.functionspace(mesh, P_element)

p = fem.Function(P, name="cumulative_plastic_strain")

dp = fem.Function(P, name="incremental_plastic_strain")

sigma_n = fem.Function(S, name="stress_n")

Defining the external operator#

During the automatic differentiation of the form \(F\), the following terms will appear in the Jacobian

where the “trial” part \(\boldsymbol{\varepsilon}(\boldsymbol{\hat{u}})\) will be handled by the framework and the derivative of the operator \(\frac{\mathrm{d} \boldsymbol{\sigma}}{\mathrm{d} \boldsymbol{\varepsilon}}\) must be implemented by the user. In this tutorial, we implement the derivative using the Numba package.

First of all, we implement the return-mapping procedure locally in the

function _kernel. It computes the values of the stress tensor, the tangent

moduli and the increment of cumulative plastic strain at a single Gausse

node. For more details, visit the original

implementation

of this problem for the legacy FEniCS 2019.

Then we iterate over each Gauss node and compute the quantities of interest

globally in the return_mapping function with the @numba.njit decorator.

This guarantees that the function will be compiled during its first call and

ordinary for-loops will be efficiently processed.

num_quadrature_points = P_element.dim

@numba.njit

def return_mapping(deps_, sigma_n_, p_):

"""Performs the return-mapping procedure."""

num_cells = deps_.shape[0]

C_tang_ = np.empty((num_cells, num_quadrature_points, 4, 4), dtype=PETSc.ScalarType)

sigma_ = np.empty_like(sigma_n_)

dp_ = np.empty_like(p_)

def _kernel(deps_local, sigma_n_local, p_local):

"""Performs the return-mapping procedure locally."""

sigma_elastic = sigma_n_local + C_elas @ deps_local

s = deviatoric @ sigma_elastic

sigma_eq = np.sqrt(3.0 / 2.0 * np.dot(s, s))

f_elastic = sigma_eq - sigma_0 - H * p_local

f_elastic_plus = (f_elastic + np.sqrt(f_elastic**2)) / 2.0

dp = f_elastic_plus / (3 * mu + H)

n_elas = s / sigma_eq * f_elastic_plus / f_elastic

beta = 3 * mu * dp / sigma_eq

sigma = sigma_elastic - beta * s

n_elas_matrix = np.outer(n_elas, n_elas)

C_tang = C_elas - 3 * mu * (3 * mu / (3 * mu + H) - beta) * n_elas_matrix - 2 * mu * beta * deviatoric

return C_tang, sigma, dp

for i in range(0, num_cells):

for j in range(0, num_quadrature_points):

C_tang_[i, j], sigma_[i, j], dp_[i, j] = _kernel(deps_[i, j], sigma_n_[i, j], p_[i, j])

return C_tang_, sigma_, dp_

Now nothing stops us from defining the implementation of the external operator

derivative (the tangent tensor \(\boldsymbol{C}_\text{tang}\)) in the

function C_tang_impl. It returns global values of the derivative, stress

tensor and the cumulative plastic increment.

def C_tang_impl(deps):

num_cells, num_quadrature_points, _ = deps.shape

deps_ = deps.reshape((num_cells, num_quadrature_points, 4))

sigma_n_ = sigma_n.x.array.reshape((num_cells, num_quadrature_points, 4))

p_ = p.x.array.reshape((num_cells, num_quadrature_points))

C_tang_, sigma_, dp_ = return_mapping(deps_, sigma_n_, p_)

return C_tang_.reshape(-1), sigma_.reshape(-1), dp_.reshape(-1)

It is worth noting that at the time of the derivative evaluation, we compute the

values of the external operator as well. Thus, there is no need for a separate

implementation of the operator \(\boldsymbol{\sigma}\). We will reuse the output

of the C_tang_impl to update values of the external operator further in the

Newton loop.

def sigma_external(derivatives):

if derivatives == (1,):

return C_tang_impl

else:

raise NotImplementedError(f"No external function is defined for the requested derivative {derivatives}.")

sigma.external_function = sigma_external

Note

The framework allows implementations of external operators and its derivatives

to return additional outputs. In our example, alongside with the values of the

derivative, the function C_tang_impl returns, the values of the stress tensor

and the cumulative plastic increment. Both additional outputs may be reused by

the user afterwards in the Newton loop.

Form manipulations#

As in the previous tutorials before solving the problem we need to perform some transformation of both linear and bilinear forms.

u_hat = ufl.TrialFunction(V)

J = ufl.derivative(F, Du, u_hat)

J_expanded = ufl.algorithms.expand_derivatives(J)

F_replaced, F_external_operators = replace_external_operators(F)

J_replaced, J_external_operators = replace_external_operators(J_expanded)

F_form = fem.form(F_replaced)

J_form = fem.form(J_replaced)

Note

We remind that in the code above we replace FEMExternalOperator objects by

their fem.Function representatives, the coefficients which are allocated

during the call of the FEMExternalOperator constructor. The access to these

coefficients may be carried out through the field ref_coefficient of an

FEMExternalOperator object. For example, the following code returns the

finite coefficient associated with the tangent matrix

C_tang = J_external_operators[0].ref_coefficient.

Solving the problem#

Once we prepared the forms containing external operators, we can apply the

Newton method to solve the nonlinear problem that is based on that forms. For

this matter, we use NonlinearProblem, which is a high-level interface of

DOLFINx based on PETSc SNES.

petsc_options = {

"snes_type": "vinewtonrsls",

"snes_linesearch_type": "basic",

"ksp_type": "preonly",

"pc_type": "lu",

"snes_atol": 1.0e-8,

"snes_rtol": 1.0e-8,

"snes_max_it": 100,

"snes_monitor": "",

}

problem = NonlinearProblem(

F_replaced, Du, J=J_replaced, bcs=bcs, petsc_options_prefix="demo_von_mises_", petsc_options=petsc_options

)

To update external operators at each iteration of the Newton method, we provide

SNES of problem with the function constitutive_update that evaluates

external operators and updates the internal variable dp.

def constitutive_update(

F_external_operators: list[FEMExternalOperator], J_external_operators: list[FEMExternalOperator], dp: Function

):

"""Update the constitutive model by evaluating the external operators."""

evaluated_operands = evaluate_operands(F_external_operators)

# Call `C_tang_impl` that returns additional arrays `sigma_new` and `dp_new`

((_, sigma_new, dp_new),) = evaluate_external_operators(J_external_operators, evaluated_operands)

# Update external operator `sigma` via explicit copy

sigma = F_external_operators[0]

sigma.ref_coefficient.x.array[:] = sigma_new

# Update history variable

dp.x.array[:] = dp_new

def assemble_residual_with_callback(

u: Function,

F: Form,

J: Form,

bcs: Sequence[DirichletBC],

external_callback: Callable,

args_external_callback: Sequence,

snes: PETSc.SNES,

x: PETSc.Vec,

b: PETSc.Vec,

) -> None:

"""Assemble the residual at ``x`` into the vector ``b`` with a callback to

external functions.

Prior to assembling the residual and after updating the solution ``u``, the

function ``external_callback`` with input arguments ``args_external_callback``

is called.

A function conforming to the interface expected by ``SNES.setFunction`` can

be created by fixing the first 5 arguments, e.g. (cf.

``dolfinx.fem.petsc.assemble_residual``):

Example::

snes = PETSc.SNES().create(mesh.comm)

assemble_residual = functools.partial(

dolfinx.fem.petsc.assemble_residual, u, F, J, bcs,

external_callback, args_external_callback)

snes.setFunction(assemble_residual, b)

Args:

u: Function tied to the solution vector within the residual and

Jacobian.

F: Form of the residual.

J: Form of the Jacobian.

bcs: List of Dirichlet boundary conditions to lift the residual.

external_callback: A callback function to call prior to assembling the

residual.

args_external_callback: Arguments to pass to the external callback

function.

snes: The solver instance.

x: The vector containing the point to evaluate the residual at.

b: Vector to assemble the residual into.

"""

x.ghostUpdate(addv=PETSc.InsertMode.INSERT, mode=PETSc.ScatterMode.FORWARD)

x.copy(u.x.petsc_vec)

u.x.scatter_forward()

# Call external functions, e.g. evaluation of external operators

external_callback(*args_external_callback)

with b.localForm() as b_local:

b_local.set(0.0)

assemble_vector(b, F)

apply_lifting(b, [J], [bcs], [x], -1.0)

b.ghostUpdate(addv=PETSc.InsertMode.ADD, mode=PETSc.ScatterMode.REVERSE)

set_bc(b, bcs, x, -1.0)

assemble_residual_with_callback_ = partial(

assemble_residual_with_callback,

problem.u,

problem.F,

problem.J,

bcs,

constitutive_update, # external callback with respect to SNES

[F_external_operators, J_external_operators, dp], # input arguments of the callback

)

# Set the custom residual assembly function with the one that calls

# `constitutive_update`

problem.solver.setFunction(assemble_residual_with_callback_, problem.b)

Now we are ready to solve the problem.

u = fem.Function(V, name="displacement")

x_point = np.array([[R_i, 0, 0]])

cells, points_on_process = find_cell_by_point(mesh, x_point)

q_lim = 2.0 / np.sqrt(3.0) * np.log(R_e / R_i) * sigma_0

num_increments = 20

load_steps = np.linspace(0, 1.1, num_increments, endpoint=True) ** 0.5

loadings = q_lim * load_steps

results = np.zeros((num_increments, 2))

eps = np.finfo(PETSc.ScalarType).eps

for i, loading_v in enumerate(loadings):

if MPI.COMM_WORLD.rank == 0:

print(f"Load increment #{i}, load: {loading_v:.3f}")

loading.value = loading_v

Du.x.array[:] = eps

_ = problem.solve()

iters = problem.solver.getIterationNumber()

print(f"\tInner Newton iterations: {iters}")

u.x.petsc_vec.axpy(1.0, Du.x.petsc_vec)

u.x.scatter_forward()

p.x.petsc_vec.axpy(1.0, dp.x.petsc_vec)

sigma_n.x.array[:] = sigma.ref_coefficient.x.array

if len(points_on_process) > 0:

results[i, :] = (u.eval(points_on_process, cells)[0], loading.value / q_lim)

Load increment #0, load: 0.000

0 SNES Function norm 9.735974110732e-11

Inner Newton iterations: 0

Load increment #1, load: 18.224

0 SNES Function norm 8.599242028004e+00

1 SNES Function norm 3.165890211455e-13

Inner Newton iterations: 1

Load increment #2, load: 25.772

0 SNES Function norm 3.561922674129e+00

1 SNES Function norm 1.357157411047e-13

Inner Newton iterations: 1

Load increment #3, load: 31.564

0 SNES Function norm 2.733159396954e+00

1 SNES Function norm 1.072933445785e-13

Inner Newton iterations: 1

Load increment #4, load: 36.447

0 SNES Function norm 2.304159956925e+00

1 SNES Function norm 8.826606400958e-14

Inner Newton iterations: 1

Load increment #5, load: 40.749

0 SNES Function norm 2.030005673584e+00

1 SNES Function norm 8.760862482722e-14

Inner Newton iterations: 1

Load increment #6, load: 44.638

0 SNES Function norm 1.835265413718e+00

1 SNES Function norm 7.675857001799e-14

Inner Newton iterations: 1

Load increment #7, load: 48.215

0 SNES Function norm 1.687700726449e+00

1 SNES Function norm 7.036021926694e-14

Inner Newton iterations: 1

Load increment #8, load: 51.544

0 SNES Function norm 1.570873534513e+00

1 SNES Function norm 7.364204850506e-14

Inner Newton iterations: 1

Load increment #9, load: 54.671

0 SNES Function norm 1.475396679750e+00

1 SNES Function norm 7.073939373632e-14

Inner Newton iterations: 1

Load increment #10, load: 57.628

0 SNES Function norm 1.395464875528e+00

1 SNES Function norm 6.564541668812e-14

Inner Newton iterations: 1

Load increment #11, load: 60.441

0 SNES Function norm 1.327268328808e+00

1 SNES Function norm 5.538226865341e-14

Inner Newton iterations: 1

Load increment #12, load: 63.128

0 SNES Function norm 1.268188909827e+00

1 SNES Function norm 1.489301007183e+00

2 SNES Function norm 2.401127969078e-02

3 SNES Function norm 3.059447962573e-06

4 SNES Function norm 8.495063478328e-14

Inner Newton iterations: 4

Load increment #13, load: 65.706

0 SNES Function norm 1.216359863927e+00

1 SNES Function norm 1.864429452635e+00

2 SNES Function norm 1.849648275577e-02

3 SNES Function norm 1.728901268485e-06

4 SNES Function norm 6.256848959742e-14

Inner Newton iterations: 4

Load increment #14, load: 68.186

0 SNES Function norm 1.170409392647e+00

1 SNES Function norm 2.904530387837e+00

2 SNES Function norm 5.874399460844e-02

3 SNES Function norm 6.654806154631e-05

4 SNES Function norm 2.104061853646e-10

Inner Newton iterations: 4

Load increment #15, load: 70.580

0 SNES Function norm 1.129303709772e+00

1 SNES Function norm 2.706931012242e+00

2 SNES Function norm 1.412797504674e-01

3 SNES Function norm 2.522387752053e-03

4 SNES Function norm 4.993407400421e-07

5 SNES Function norm 7.657440001862e-14

Inner Newton iterations: 5

Load increment #16, load: 72.894

0 SNES Function norm 1.092246947552e+00

1 SNES Function norm 1.479909211759e+00

2 SNES Function norm 3.240106152237e-01

3 SNES Function norm 1.627286033445e-02

4 SNES Function norm 1.521056575447e-05

5 SNES Function norm 1.630985707841e-11

Inner Newton iterations: 5

Load increment #17, load: 75.138

0 SNES Function norm 1.058615069702e+00

Inner Newton iterations: 0

Load increment #18, load: 77.316

Inner Newton iterations: 0

Load increment #19, load: 79.435

Inner Newton iterations: 0

Post-processing#

In order to verify the correctness of obtained results, we perform their

comparison against a “pure UFl” implementation. Thanks to simplicity of the von

Mises model we can express stress tensor and tangent moduli analytically within

the variational setting and so in UFL. Such a performant implementation is

presented by the function plasticity_von_mises_pure_ufl.

results_pure_ufl = plasticity_von_mises_pure_ufl(verbose=True)

Load increment #0, load: 18.224

0 SNES Function norm 8.599242028001e+00

1 SNES Function norm 3.707763086477e-13

Inner Newton iterations: 1

Load increment #1, load: 25.772

0 SNES Function norm 5.037319353875e+00

1 SNES Function norm 2.173179644185e-13

Inner Newton iterations: 1

Load increment #2, load: 31.564

0 SNES Function norm 8.287632771751e-01

1 SNES Function norm 6.160304246034e-14

Inner Newton iterations: 1

Load increment #3, load: 36.447

0 SNES Function norm 4.289994400290e-01

1 SNES Function norm 6.039495744435e-14

Inner Newton iterations: 1

Load increment #4, load: 40.749

0 SNES Function norm 2.741542833413e-01

1 SNES Function norm 4.666375712008e-14

Inner Newton iterations: 1

Load increment #5, load: 44.638

0 SNES Function norm 1.947402598663e-01

1 SNES Function norm 4.251745451590e-14

Inner Newton iterations: 1

Load increment #6, load: 48.215

0 SNES Function norm 1.475646872682e-01

1 SNES Function norm 3.761036553781e-14

Inner Newton iterations: 1

Load increment #7, load: 51.544

0 SNES Function norm 1.168271919368e-01

1 SNES Function norm 5.622850203615e-14

Inner Newton iterations: 1

Load increment #8, load: 54.671

0 SNES Function norm 9.547685476257e-02

1 SNES Function norm 4.833305264468e-14

Inner Newton iterations: 1

Load increment #9, load: 57.628

0 SNES Function norm 7.993180422194e-02

1 SNES Function norm 4.922986199823e-14

Inner Newton iterations: 1

Load increment #10, load: 60.441

0 SNES Function norm 6.819654672002e-02

1 SNES Function norm 4.812206568573e-14

Inner Newton iterations: 1

Load increment #11, load: 63.128

0 SNES Function norm 1.543311382782e+00

1 SNES Function norm 2.268979604869e-02

2 SNES Function norm 2.757984919757e-06

3 SNES Function norm 7.433019229862e-14

Inner Newton iterations: 3

Load increment #12, load: 65.706

0 SNES Function norm 1.038273203056e+00

1 SNES Function norm 1.006639718546e-01

2 SNES Function norm 1.443589632202e-05

3 SNES Function norm 9.590114238792e-13

Inner Newton iterations: 3

Load increment #13, load: 68.186

0 SNES Function norm 2.135088592677e+00

1 SNES Function norm 2.801707974058e-02

2 SNES Function norm 7.704334123909e-06

3 SNES Function norm 1.241787364227e-12

Inner Newton iterations: 3

Load increment #14, load: 70.580

0 SNES Function norm 2.189846156364e+00

1 SNES Function norm 4.326554644411e-02

2 SNES Function norm 4.164752626486e-05

3 SNES Function norm 7.218767329932e-11

Inner Newton iterations: 3

Load increment #15, load: 72.894

0 SNES Function norm 1.989247993122e+00

1 SNES Function norm 2.999837010408e-02

2 SNES Function norm 2.418579146815e-05

3 SNES Function norm 2.069597968236e-11

Inner Newton iterations: 3

Load increment #16, load: 75.138

0 SNES Function norm 2.168612764046e+00

1 SNES Function norm 5.332317489711e-02

2 SNES Function norm 5.635404365384e-05

3 SNES Function norm 2.010954001056e-10

Inner Newton iterations: 3

Load increment #17, load: 77.316

0 SNES Function norm 5.624365630304e+00

1 SNES Function norm 4.164736040335e+00

2 SNES Function norm 5.705502335825e-01

3 SNES Function norm 6.137244286188e-03

4 SNES Function norm 6.918232637881e-07

5 SNES Function norm 6.190699324132e-13

Inner Newton iterations: 5

Load increment #18, load: 79.435

0 SNES Function norm 6.050025604365e+00

1 SNES Function norm 6.598086373582e-01

2 SNES Function norm 2.425716665943e-03

3 SNES Function norm 8.195869356106e-08

4 SNES Function norm 1.057995509210e-12

Inner Newton iterations: 4

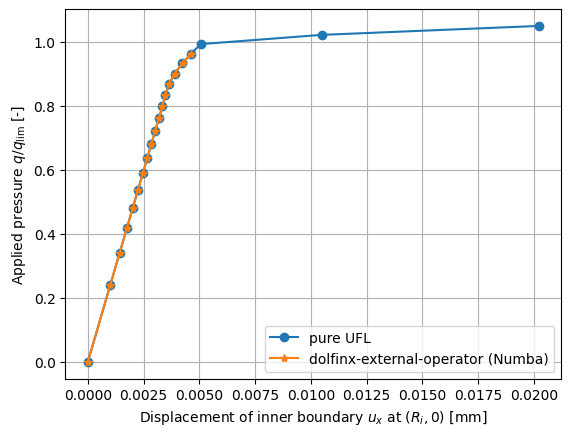

Here below we plot the displacement of the inner boundary of the cylinder \(u_x(R_i, 0)\) with respect to the applied pressure in the von Mises model with isotropic hardening. The plastic deformations are reached at the pressure \(q_{\lim}\) equal to the analytical collapse load for perfect plasticity.

if len(points_on_process) > 0:

plt.plot(results_pure_ufl[:, 0], results_pure_ufl[:, 1], "o-", label="pure UFL")

plt.plot(results[:, 0], results[:, 1], "*-", label="dolfinx-external-operator (Numba)")

plt.xlabel(r"Displacement of inner boundary $u_x$ at $(R_i, 0)$ [mm]")

plt.ylabel(r"Applied pressure $q/q_{\text{lim}}$ [-]")

plt.legend()

plt.grid()

plt.savefig("output.png")

plt.show()

References#

Marc Bonnet, Attilio Frangi, and Christian Rey. The finite element method in solid mechanics. McGraw Hill Education, 2014. URL: https://hal.science/hal-01083772.