Plasticity of von Mises#

This tutorial aims to demonstrate an efficient implementation of the plasticity

model of von Mises using an external operator defining the elastoplastic

constitutive relations written with the help of the 3rd-party package Numba.

Here we consider a cylinder expansion problem in the two-dimensional case in a

symmetric formulation.

This tutorial is based on the original implementation of the problem via legacy FEniCS 2019 and its extension for the modern FEniCSx in the setting of convex optimization. A detailed conclusion of the von Mises plastic model in the case of the cylinder expansion problem can be found in [Bonnet et al., 2014]. Do not hesitate to visit the mentioned sources for more information.

We assume the knowledge of the return-mapping procedure, commonly used in the solid mechanics community to solve elastoplasticity problems.

Notation#

Denoting the displacement vector \(\boldsymbol{u}\) we define the strain tensor \(\boldsymbol{\varepsilon}\) as follows

Throughout the tutorial, we stick to the Mandel-Voigt notation, according to which the stress tensor \(\boldsymbol{\sigma}\) and the strain tensor \(\boldsymbol{\varepsilon}\) are written as 4-size vectors with the following components

Denoting the deviatoric operator \(\mathrm{dev}\), we introduce two additional quantities of interest: the cumulative plastic strain \(p\) and the equivalent stress \(\sigma_\text{eq}\) defined by the following formulas:

where \(\boldsymbol{e} = \mathrm{dev}\boldsymbol{\varepsilon}\) and \(\boldsymbol{s} = \mathrm{dev}\boldsymbol{\sigma}\) are deviatoric parts of the stain and stress tensors respectively.

Problem formulation#

The domain of the problem \(\Omega\) represents the first quarter of the hollow cylinder with inner \(R_i\) and outer \(R_o\) radii, where symmetry conditions are set on the left and bottom sides and pressure is set on the inner wall \(\partial\Omega_\text{inner}\). The behaviour of cylinder material is defined by the von Mises yield criterion \(f\) with the linear isotropic hardening law (3)

where \(\sigma_0\) is a uniaxial strength and \(H\) is an isotropic hardening modulus, which is defined through the Young modulus \(E\) and the tangent elastic modulus \(E_t = \frac{EH}{E+H}\).

Let V be the functional space of admissible displacement fields. Then, the weak formulation of this problem can be written as follows:

Find \(\boldsymbol{u} \in V\) such that

The external force \(F_{\text{ext}}(\boldsymbol{v})\) represents the pressure inside the cylinder and is written as the following Neumann condition

where the vector \(\boldsymbol{n}\) is a normal to the cylinder surface and the loading parameter \(q\) is progressively increased from 0 to \(q_\text{lim} = \frac{2}{\sqrt{3}}\sigma_0\log\left(\frac{R_o}{R_i}\right)\), the analytical collapse load for the perfect plasticity model without hardening.

The modelling is performed under assumptions of the plane strain and an associative plasticity law.

In this tutorial, we treat the stress tensor \(\boldsymbol{\sigma}\) as an

external operator acting on the strain tensor \(\boldsymbol{\varepsilon}(\boldsymbol{u})\) and

represent it through a FEMExternalOperator object. By the implementation of

this external operator, we mean an implementation of the return-mapping

procedure, the most common approach to solve plasticity problems. With the

help of this procedure, we compute both values of the stress tensor

\(\boldsymbol{\sigma}\) and its derivative, so-called the tangent stiffness

matrix \(\boldsymbol{C}_\text{tang}\).

As before, in order to solve the nonlinear equation (4) we need to compute the Gateaux derivative of \(F\) in the direction \(\boldsymbol{\hat{u}} \in V\):

The advantage of the von Mises model is that the return-mapping procedure may be performed analytically, so the stress tensor and the tangent stiffness matrix may be expressed explicitly using any package. In our case, we the Numba library to define the behaviour of the external operator and its derivative.

Implementation#

Preamble#

from mpi4py import MPI

from petsc4py import PETSc

import matplotlib.pyplot as plt

import numba

import numpy as np

from plasticity_von_mises_pure_ufl import plasticity_von_mises_interpolation, plasticity_von_mises_pure_ufl

from solvers import LinearProblem

from utilities import build_cylinder_quarter, find_cell_by_point

import basix

import ufl

from dolfinx import common, fem

from dolfinx_external_operator import (

FEMExternalOperator,

evaluate_external_operators,

evaluate_operands,

replace_external_operators,

)

Here we define geometrical and material parameters of the problem as well as some useful constants.

R_e, R_i = 1.3, 1.0 # external/internal radius

E, nu = 70e3, 0.3 # elastic parameters

E_tangent = E / 100.0 # tangent modulus

H = E * E_tangent / (E - E_tangent) # hardening modulus

sigma_0 = 250.0 # yield strength

lmbda = E * nu / (1.0 + nu) / (1.0 - 2.0 * nu)

mu = E / 2.0 / (1.0 + nu)

# stiffness matrix

C_elas = np.array(

[

[lmbda + 2.0 * mu, lmbda, lmbda, 0.0],

[lmbda, lmbda + 2.0 * mu, lmbda, 0.0],

[lmbda, lmbda, lmbda + 2.0 * mu, 0.0],

[0.0, 0.0, 0.0, 2.0 * mu],

],

dtype=PETSc.ScalarType,

)

deviatoric = np.eye(4, dtype=PETSc.ScalarType)

deviatoric[:3, :3] -= np.full((3, 3), 1.0 / 3.0, dtype=PETSc.ScalarType)

mesh, facet_tags, facet_tags_labels = build_cylinder_quarter()

k_u = 2

V = fem.functionspace(mesh, ("Lagrange", k_u, (2,)))

# Boundary conditions

bottom_facets = facet_tags.find(facet_tags_labels["Lx"])

left_facets = facet_tags.find(facet_tags_labels["Ly"])

bottom_dofs_y = fem.locate_dofs_topological(V.sub(1), mesh.topology.dim - 1, bottom_facets)

left_dofs_x = fem.locate_dofs_topological(V.sub(0), mesh.topology.dim - 1, left_facets)

sym_bottom = fem.dirichletbc(np.array(0.0, dtype=PETSc.ScalarType), bottom_dofs_y, V.sub(1))

sym_left = fem.dirichletbc(np.array(0.0, dtype=PETSc.ScalarType), left_dofs_x, V.sub(0))

bcs = [sym_bottom, sym_left]

def epsilon(v):

grad_v = ufl.grad(v)

return ufl.as_vector([grad_v[0, 0], grad_v[1, 1], 0, np.sqrt(2.0) * 0.5 * (grad_v[0, 1] + grad_v[1, 0])])

k_stress = 2 * (k_u - 1)

ds = ufl.Measure(

"ds",

domain=mesh,

subdomain_data=facet_tags,

metadata={"quadrature_degree": k_stress, "quadrature_scheme": "default"},

)

dx = ufl.Measure(

"dx",

domain=mesh,

metadata={"quadrature_degree": k_stress, "quadrature_scheme": "default"},

)

Du = fem.Function(V, name="displacement_increment")

S_element = basix.ufl.quadrature_element(mesh.topology.cell_name(), degree=k_stress, value_shape=(4,))

S = fem.functionspace(mesh, S_element)

sigma = FEMExternalOperator(epsilon(Du), function_space=S)

n = ufl.FacetNormal(mesh)

loading = fem.Constant(mesh, PETSc.ScalarType(0.0))

v = ufl.TestFunction(V)

F = ufl.inner(sigma, epsilon(v)) * dx - loading * ufl.inner(v, n) * ds(facet_tags_labels["inner"])

# Internal state

P_element = basix.ufl.quadrature_element(mesh.topology.cell_name(), degree=k_stress, value_shape=())

P = fem.functionspace(mesh, P_element)

p = fem.Function(P, name="cumulative_plastic_strain")

dp = fem.Function(P, name="incremental_plastic_strain")

sigma_n = fem.Function(S, name="stress_n")

Defining the external operator#

During the automatic differentiation of the form \(F\), the following terms will appear in the Jacobian

where the “trial” part \(\boldsymbol{\varepsilon}(\boldsymbol{\hat{u}})\) will be handled by the framework and the derivative of the operator \(\frac{\mathrm{d} \boldsymbol{\sigma}}{\mathrm{d} \boldsymbol{\varepsilon}}\) must be implemented by the user. In this tutorial, we implement the derivative using the Numba package.

First of all, we implement the return-mapping procedure locally in the

function _kernel. It computes the values of the stress tensor, the tangent

stiffness matrix and the increment of cumulative plastic strain at a single

Gausse node. For more details, visit the original

implementation

of this problem for the legacy FEniCS 2019.

Then we iterate over each Gauss node and compute the quantities of interest

globally in the return_mapping function with the @numba.njit decorator.

This guarantees that the function will be compiled during its first call and

ordinary for-loops will be efficiently processed.

num_quadrature_points = P_element.dim

@numba.njit

def return_mapping(deps_, sigma_n_, p_):

"""Performs the return-mapping procedure."""

num_cells = deps_.shape[0]

C_tang_ = np.empty((num_cells, num_quadrature_points, 4, 4), dtype=PETSc.ScalarType)

sigma_ = np.empty_like(sigma_n_)

dp_ = np.empty_like(p_)

def _kernel(deps_local, sigma_n_local, p_local):

"""Performs the return-mapping procedure locally."""

sigma_elastic = sigma_n_local + C_elas @ deps_local

s = deviatoric @ sigma_elastic

sigma_eq = np.sqrt(3.0 / 2.0 * np.dot(s, s))

f_elastic = sigma_eq - sigma_0 - H * p_local

f_elastic_plus = (f_elastic + np.sqrt(f_elastic**2)) / 2.0

dp = f_elastic_plus / (3 * mu + H)

n_elas = s / sigma_eq * f_elastic_plus / f_elastic

beta = 3 * mu * dp / sigma_eq

sigma = sigma_elastic - beta * s

n_elas_matrix = np.outer(n_elas, n_elas)

C_tang = C_elas - 3 * mu * (3 * mu / (3 * mu + H) - beta) * n_elas_matrix - 2 * mu * beta * deviatoric

return C_tang, sigma, dp

for i in range(0, num_cells):

for j in range(0, num_quadrature_points):

C_tang_[i, j], sigma_[i, j], dp_[i, j] = _kernel(deps_[i, j], sigma_n_[i, j], p_[i, j])

return C_tang_, sigma_, dp_

Now nothing stops us from defining the implementation of the external operator

derivative (the stiffness tangent tensor \(\boldsymbol{C}_\text{tang}\)) in the

function C_tang_impl. It returns global values of the derivative, stress

tensor and the cumulative plastic increment.

def C_tang_impl(deps):

num_cells = deps.shape[0]

num_quadrature_points = int(deps.shape[1] / 4)

deps_ = deps.reshape((num_cells, num_quadrature_points, 4))

sigma_n_ = sigma_n.x.array.reshape((num_cells, num_quadrature_points, 4))

p_ = p.x.array.reshape((num_cells, num_quadrature_points))

C_tang_, sigma_, dp_ = return_mapping(deps_, sigma_n_, p_)

return C_tang_.reshape(-1), sigma_.reshape(-1), dp_.reshape(-1)

It is worth noting that at the time of the derivative evaluation, we compute the

values of the external operator as well. Thus, there is no need for a separate

implementation of the operator \(\boldsymbol{\sigma}\). We will reuse the output

of the C_tang_impl to update values of the external operator further in the

Newton loop.

def sigma_external(derivatives):

if derivatives == (1,):

return C_tang_impl

else:

return NotImplementedError

sigma.external_function = sigma_external

Note

The framework allows implementations of external operators and its derivatives

to return additional outputs. In our example, alongside with the values of the

derivative, the function C_tang_impl returns, the values of the stress tensor

and the cumulative plastic increment. Both additional outputs may be reused by

the user afterwards in the Newton loop.

Form manipulations#

As in the previous tutorials before solving the problem we need to perform some transformation of both linear and bilinear forms.

u_hat = ufl.TrialFunction(V)

J = ufl.derivative(F, Du, u_hat)

J_expanded = ufl.algorithms.expand_derivatives(J)

F_replaced, F_external_operators = replace_external_operators(F)

J_replaced, J_external_operators = replace_external_operators(J_expanded)

F_form = fem.form(F_replaced)

J_form = fem.form(J_replaced)

Note

We remind that in the code above we replace FEMExternalOperator objects by

their fem.Function representatives, the coefficients which are allocated

during the call of the FEMExternalOperator constructor. The access to these

coefficients may be carried out through the field ref_coefficient of an

FEMExternalOperator object. For example, the following code returns the

finite coefficient associated with the tangent matrix

C_tang = J_external_operators[0].ref_coefficient.

Variables initialization and compilation#

Before assembling the forms, we have to initialize the external operators. In particular, the tangent matrix should be equal to the elastic one during the first loading step, so to initialize the former, we evaluate external operators for a close-to-zero displacement field.

At the same time, we estimate the compilation overhead caused by the first call of JIT-ed Numba functions.

# We need to initialize `Du` with small values in order to avoid the division by

# zero error

eps = np.finfo(PETSc.ScalarType).eps

Du.x.array[:] = eps

timer = common.Timer("DOLFINx_timer")

timer.start()

evaluated_operands = evaluate_operands(F_external_operators)

_ = evaluate_external_operators(J_external_operators, evaluated_operands)

timer.stop()

pass_1 = timer.elapsed()[0]

timer.start()

evaluated_operands = evaluate_operands(F_external_operators)

_ = evaluate_external_operators(J_external_operators, evaluated_operands)

timer.stop()

pass_2 = timer.elapsed()[0]

print(f"\nNumba's JIT compilation overhead: {pass_1 - pass_2}")

Numba's JIT compilation overhead: 3.45

Solving the problem#

Solving the problem is carried out in a manually implemented Newton solver.

u = fem.Function(V, name="displacement")

du = fem.Function(V, name="Newton_correction")

external_operator_problem = LinearProblem(J_replaced, F_replaced, Du, bcs=bcs)

# Defining a cell containing (Ri, 0) point, where we calculate a value of u

# In order to run this program in parallel we need capture the process, to which

# this point is attached

x_point = np.array([[R_i, 0, 0]])

cells, points_on_process = find_cell_by_point(mesh, x_point)

q_lim = 2.0 / np.sqrt(3.0) * np.log(R_e / R_i) * sigma_0

num_increments = 20

max_iterations, relative_tolerance = 200, 1e-8

load_steps = (np.linspace(0, 1.1, num_increments, endpoint=True) ** 0.5)[1:]

loadings = q_lim * load_steps

results = np.zeros((num_increments, 2))

for i, loading_v in enumerate(loadings):

loading.value = loading_v

external_operator_problem.assemble_vector()

residual_0 = residual = external_operator_problem.b.norm()

Du.x.array[:] = 0.0

if MPI.COMM_WORLD.rank == 0:

print(f"\nresidual , {residual} \n increment: {i+1!s}, load = {loading.value}")

for iteration in range(0, max_iterations):

if residual / residual_0 < relative_tolerance:

break

external_operator_problem.assemble_matrix()

external_operator_problem.solve(du)

du.x.scatter_forward()

Du.vector.axpy(-1.0, du.vector)

Du.x.scatter_forward()

evaluated_operands = evaluate_operands(F_external_operators)

# Implementation of an external operator may return several outputs and

# not only its evaluation. For example, `C_tang_impl` returns a tuple of

# Numpy-arrays with values of `C_tang`, `sigma` and `dp`.

((_, sigma_new, dp_new),) = evaluate_external_operators(J_external_operators, evaluated_operands)

# In order to update the values of the external operator we may directly

# access them and avoid the call of

# `evaluate_external_operators(F_external_operators, evaluated_operands).`

sigma.ref_coefficient.x.array[:] = sigma_new

dp.x.array[:] = dp_new

external_operator_problem.assemble_vector()

residual = external_operator_problem.b.norm()

if MPI.COMM_WORLD.rank == 0:

print(f" it# {iteration} residual: {residual}")

u.vector.axpy(1.0, Du.vector)

u.x.scatter_forward()

# Taking into account the history of loading

p.vector.axpy(1.0, dp.vector)

# skip scatter forward, p is not ghosted.

sigma_n.x.array[:] = sigma.ref_coefficient.x.array

# skip scatter forward, sigma is not ghosted.

if len(points_on_process) > 0:

results[i + 1, :] = (-u.eval(points_on_process, cells)[0], loading.value / q_lim)

residual , 8.599242028001447

increment: 1, load = 18.22357591920427

it# 0 residual: 2.86659570639356e-13

residual , 3.561922674126921

increment: 2, load = 25.772028219874418

it# 0 residual: 1.1619299386056414e-13

residual , 2.7331593969517707

increment: 3, load = 31.564159387650495

it# 0 residual: 1.0946480970885102e-13

residual , 2.304159956922752

increment: 4, load = 36.44715183840854

it# 0 residual: 8.656123856986615e-14

residual , 2.030005673581492

increment: 5, load = 40.74915454846896

it# 0 residual: 8.168071528973626e-14

residual , 1.8352654137151767

increment: 6, load = 44.63846229092138

it# 0 residual: 7.192300232670426e-14

residual , 1.6877007264469919

increment: 7, load = 48.21504988051979

it# 0 residual: 7.085573696289195e-14

residual , 1.5708735345101743

increment: 8, load = 51.544056439748836

it# 0 residual: 6.593085701564125e-14

residual , 1.4753966797476157

increment: 9, load = 54.67072775761281

it# 0 residual: 6.515849416789851e-14

residual , 1.3954648755256611

increment: 10, load = 57.628007017682094

it# 0 residual: 6.730873016584998e-14

residual , 1.3272683288056422

increment: 11, load = 60.44076366255657

it# 0 residual: 6.544208278137888e-14

residual , 1.268188909824636

increment: 12, load = 63.12831877530099

it# 0 residual: 1.4893010071834571

it# 1 residual: 0.024011279690787098

it# 2 residual: 3.0594479646378868e-06

it# 3 residual: 8.303498067487531e-14

residual , 1.2163598639239093

increment: 13, load = 65.70603739900179

it# 0 residual: 0.8161940858616228

it# 1 residual: 0.07723280379263806

it# 2 residual: 9.315749140976803e-06

it# 3 residual: 4.413515811511117e-13

residual , 1.1704093926445502

increment: 14, load = 68.18637745152637

it# 0 residual: 0.8359673987800559

it# 1 residual: 0.013714168292272132

it# 2 residual: 1.815711060675932e-06

it# 3 residual: 6.968459024152898e-14

residual , 1.1293037097279741

increment: 15, load = 70.57960604342466

it# 0 residual: 1.6640529483784086

it# 1 residual: 0.821481976652028

it# 2 residual: 0.002415098137142869

it# 3 residual: 9.3096662838394e-08

it# 4 residual: 6.732687003196926e-14

residual , 1.0922469475492926

increment: 16, load = 72.89430367681707

it# 0 residual: 0.6400702322368389

it# 1 residual: 0.2833799350485556

it# 2 residual: 0.014196471902242862

it# 3 residual: 7.2922851684052155e-06

it# 4 residual: 3.821350105252596e-12

residual , 1.05861506969511

increment: 17, load = 75.13772839134165

it# 0 residual: 1.9811818203618505

it# 1 residual: 0.050114056098219645

it# 2 residual: 2.3347429368046748e-05

it# 3 residual: 1.3031864124389719e-11

residual , 1.0279109246863802

increment: 18, load = 77.31608465962326

it# 0 residual: 7.1610994372466035

it# 1 residual: 4.26585685457389

it# 2 residual: 0.6035764966419548

it# 3 residual: 0.00912868907030283

it# 4 residual: 1.957348242537754e-06

it# 5 residual: 5.314889461278251e-13

residual , 0.9997328847209843

increment: 19, load = 79.43472582175275

it# 0 residual: 1.6790196670813418

it# 1 residual: 0.022175619855480548

it# 2 residual: 3.371293463438318e-06

it# 3 residual: 8.554016782829364e-13

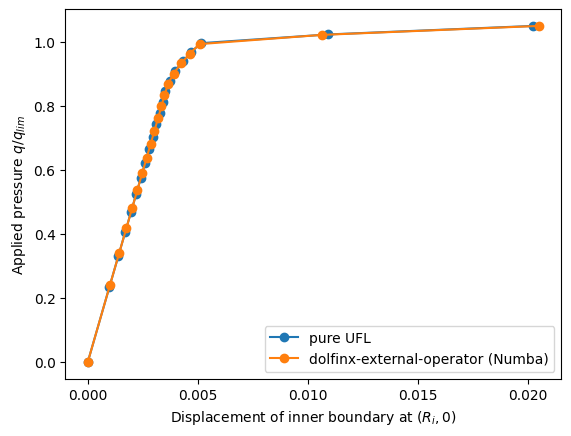

Post-processing#

results_interpolation = plasticity_von_mises_interpolation(verbose=False)

results_pure_ufl = plasticity_von_mises_pure_ufl(verbose=False)

if len(points_on_process) > 0:

plt.plot(results_pure_ufl[:, 0], results_pure_ufl[:, 1], "-o", label="pure UFL")

plt.plot(results[:, 0], results[:, 1], "-o", label="dolfinx-external-operator (Numba)")

# plt.plot(-results_interpolation[:, 0], results_interpolation[:, 1], "-o", label="interpolation")

plt.xlabel(r"Displacement of inner boundary at $(R_i, 0)$")

plt.ylabel(r"Applied pressure $q/q_{lim}$")

plt.legend()

plt.show()

Marc Bonnet, Attilio Frangi, and Christian Rey. The finite element method in solid mechanics. McGraw Hill Education, 2014. URL: https://hal.science/hal-01083772.